Sports are always moving with the times and kitesurfing is no exception. James Crook, the founder and managing director of Forty1 Kitesurfing is taking his passion for kitesurfing along with his incredible engineering prowess to find a low profile, low-cost hydrofoil for kitesurfers to attach to twin tip kiteboards. Follow his process in his own words here:

Follow his process in his own words here:

“I’ve always been curious about how things work and creating things has always been a passion since my first lego kit I was given as a child, even though back then I needed my dad’s help to make it. I’ve always liked to explore my creative side but more often my curiosity brought the technical side to the fore, the end result was 13 years as a mechanical engineer.

I always felt myself fortunate in my job, there was a lot of freedom to explore different avenues, I would never be pigeon holed into one particular area. This gave me a range of skills, from design through to the analytical. When my company moved the operations to the US and leaving myself redundant, I was left asking: How can I best make use of these skills to do something for myself? I wasn’t quite ready to go straight back into corporate life and I had a unique opportunity to find my own path.

It was a discussion with the local kite shop that sparked my interest in the hydrofoil design, when the shop owner mentioned about the hydrofoil market and how it was growing.

This gave me the perfect outlet. I’ve been kitesurfing for 5 years and love it, to work in this field would be a fantastic opportunity. A lot of products and innovation these days require electronics and software, and apart from the odd html knowledge these aren’t skills I possess. Neither, I should add, is actually manually creating things. I know what I want to achieve but the signal going from my brain to my hands seems to get rather distorted. With modern day computing and the latest 3d printer technologies, I can overcome these limitations!

So I have developed a low-cost kitefoils solution for twin tip boards that is currently under development. Off the back of a competition run by Crowdfunder in collaboration with Virgin, we are about to launch a crowdfunding campaign to fund the next stages of development and also to generate interest in the project. I’ve found it exciting to see how the project evolves and the interest in generates. How will the project look on final completion?

I’ve found it exciting to see how the project has evolved and the interest it has generated. How will the project look on final completion? Certainly, it is not what I thought it would look like when I started. I first discovered that you can put a carbon fibre skin on a 3D print and the material cost was relatively low but the fact that the process took a couple of days and that carbon fibre wasn’t the friendliest of materials to work with quickly put me off that design. I did look at the more conventional carbon fibre process, and in th, ory it is quite simple. Create the part, create the mould, get some prepreg material, get an oven, vacuum bag and compressor – now this is starting to turn into a production line and not something I’m quite prepared, or my girlfriend is prepared to allow me, to turn my conservatory into!

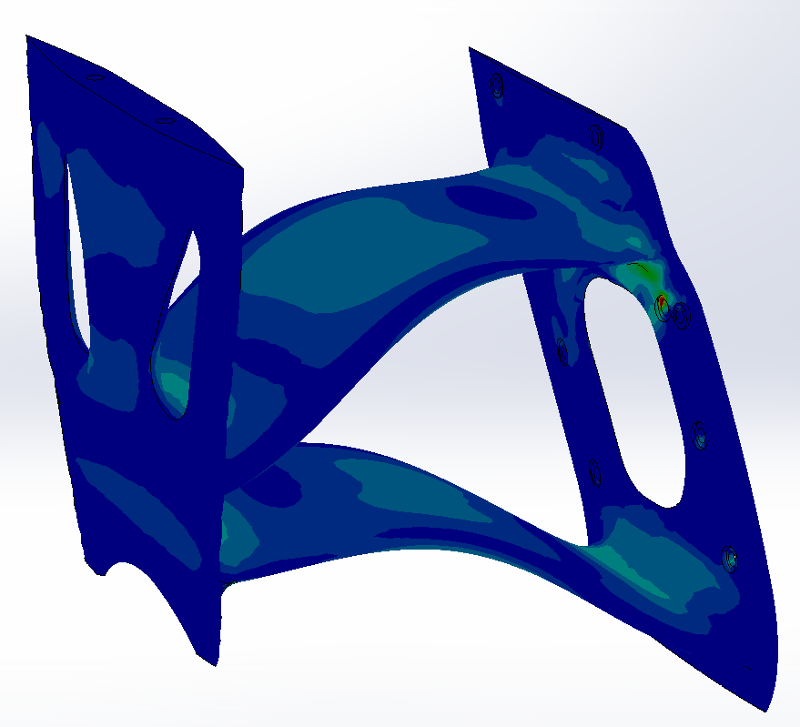

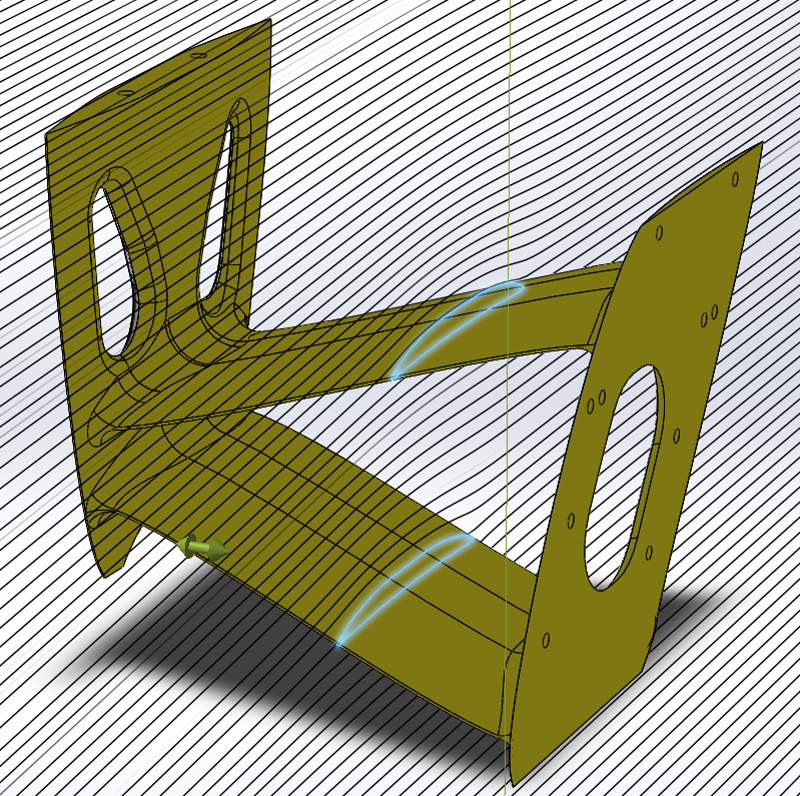

We have been modeling and analysing the design on CAD and 3D print out each iteration to test out on the water. And what of the analysis? I can run simulations to calculate the lift and the stresses the foil will go under during ideal conditions, but the foil will almost never be under these conditions, as the water gets choppy and the riders undoubtedly puts the board at various angles never imagined, not to mention the heights they can fall from. A phrase I often find myself using after designing something, ‘why on earth would you use it like that?’ Though I’m probably thankfully for humankind that not everyone’s brain is wired the same as mine!

With each iteration of the design, I can see it evolving, I can see challenges and I can see how to overcome them for the next design and I apply for design protection on each one. I sometimes wish the next design would be the final one, but when it is not, I reflect and think that when I do get to a working solution, which I will, then it it just makes it that little bit more satisfactory to look back on the journey I took, and I love to see the interest people take in it.

I love sharing my story and I really enjoy people taking an interest and being involved, so if you have read this and find yourself intrigued, please follow our progress on the hydrofoil dream at www.

How many iterations do we have left? How long is a piece of string? We learn something new each design and want to start involving others more in our journey!